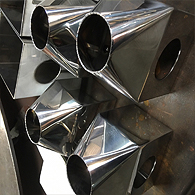

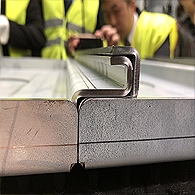

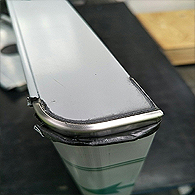

Kun Zhao Yi Precision (JKE) was established in 1999 with its business mainly engaged in laser cutting, bending, welding, rounded leveling, water jet cutting, assembly, tapping, touch welding, stamping, metal products for precision machinery processing board, parts used in medical equipment, auto parts, complete plant equipment, etc. From a professional designer to manufacturing of finished products, Kun Zhao Yi is a total solution provider for complete equipment, professional precision sheet metal manufacturing plants and various design parts factory. 「 Our objective is to establish a favorable production system with computerized scheduling for only the best in quality products. 」

In 2008 the company passed the ISO9001 certification, systematic production control, quality assurance and the 3D and 2.5D measurement standard in order to meet your requirements for distinctions in quality. While actively improving the competitiveness of the company there are plans to purchase new equipment every year. At the same time implement the “e” management ideology, introduce diversified full-service, customer-oriented, service-oriented spirit of enterprise in order to exercise greater customer care so as to garner their trust and become the best business partner.

Currently there are a total of 30 R & D professionals dealing with design drawings, production process and so on. The philosophy of the company is: “To enable customer to turn out extraordinary value added products that would result in success and prosperity.” As such the motivation of our R&D is heavily focused on customer’s requirements; and strife to understand customers’ demand. In addition, to achieve total convenience and assurance in post production processing that will exceed all standards. Furthermore, the R&D department is committed to creating a harmonious creative environment that is filled with surprises that will give assurance to our established customers and a peace of mind to our new customers.

Company Profile

About JKE

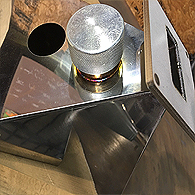

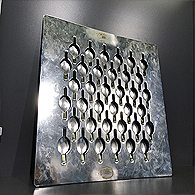

Water-jet Machining

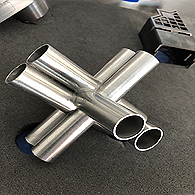

Machining for Automotive Parts

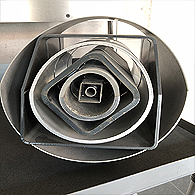

Machining for Medical Parts

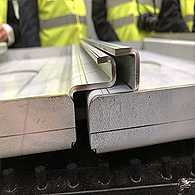

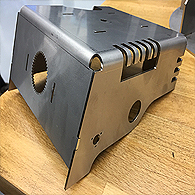

Related Sheet-Metal Processes for the facilities in Factary