Superb skills and excellent quality to create a win-win market together with you.

Advanced equipment and sophisticated technology to deliver excellent product quality, cost effectiveness that will enhance market competitiveness advantages. As such, creating a win-win market situation together with you.

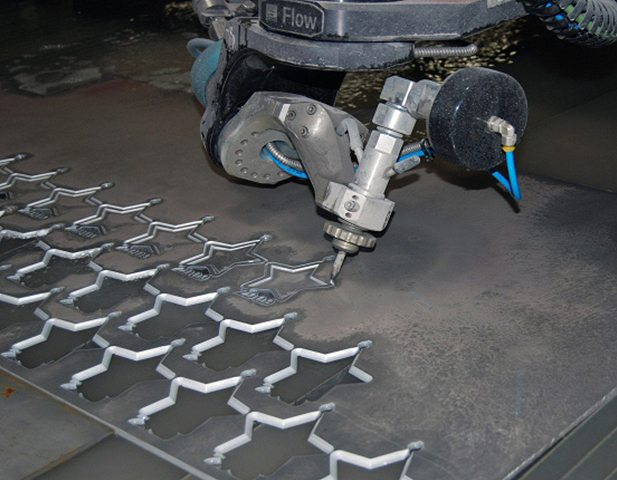

5 Axis Waterjet

Cutting Systems

Cutting Systems

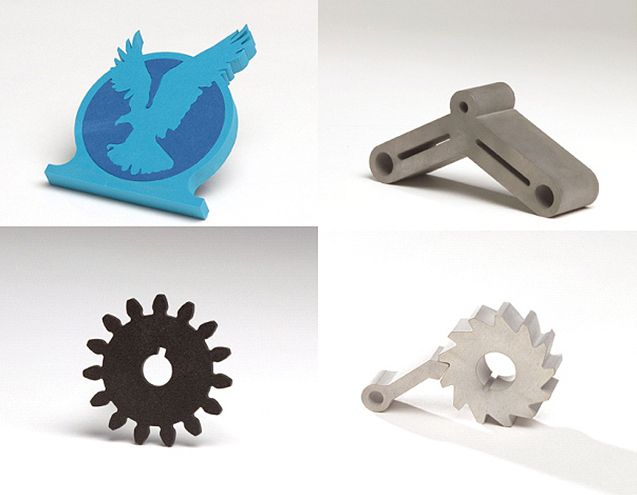

| ▲ | Capable of cutting to any shape requested and does not require secondary processing. |

| ▲ | Automobile, aerospace, stones and tiles, tools and molds, manufacturing or processing plant can obtain thickness of between 1.5mm to 200mm without having to need to carry out sectional heating for metal, stone, plastics, composites, glass, ceramics or rubber with fine quality edges. |

| ▲ | Abrasive waterjet cutting by erosion method rather than cut or heated can produce high quality edge and non-thermal effects and mechanical deformation. |

| ▲ | Narrow slit by water knife without thermal effect allows parts to be placed closely together to maximize use of raw materials. |

| ▲ | Edges by waterjet cutting are precise and levelled that allows materials to be closely placed to reduce waste, maximize material use and reduce cost. |

| ▲ | Biggest platform is 5m x 2m, 95,000 lbs 5-axials cutting for higher speed. |